I want to thank everyone here for the input. It was a really tough decision to make. I wanted to maximize performance while still getting a certain "look". Ultimately I decided on the following:

Shilen Stainless Select Match

- 308 WIN

- 24 inches

- Varmint contour

- 1:10 twist rate

- 11-degree crown

- Bead blasted finish

- Threaded barrel

I ordered the barrel from Northland Shooter's Supply and they were a pleasure to work with. I also ordered a recoil lug, barrel nut, and the tools needed to change to the barrel.

One item I did not know is that when ordering a custom barrel from Shilen they offer for no additional cost the option to send in a dummy round seated to your desired distance from the neck to the lands (freebore?).

Now I have a new question (not sure if this belongs in its own thread).

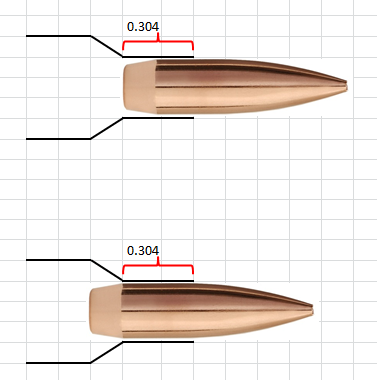

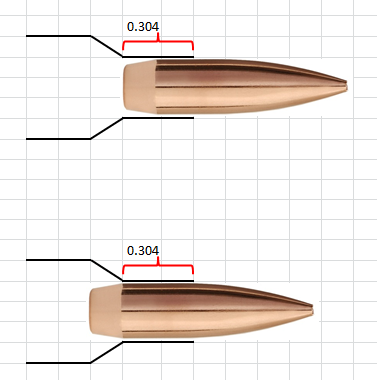

What is the ideal seating depth for a bullet to be seated into a cartridge. I have heard before that you want to seat so that the bearing surface is at least one caliber into the neck. A 308 WIN has a neck length of 0.304". My primary bullet is a 175gr SMK which has a an overall length of 1.240 (0.165 boat-tail, 0.350 bearing surface, 0.710 ogive to meplat). What I would like to confirm is that the target depth is the depth which 1) the bearing surface should be seated into the neck and not 2) the overall length which should be seated into the neck.

It would make sense to me that it would be the bearing surface (second picture) that should be at least a caliber length into the neck as opposed to the first picture which would have only 0.170 inches of the bearing surface in contact with the neck. If the second picture is the correct answer then that would mean that it is actually impossible to properly seat a 175 SMK longer than SAMI specifications / magazine length. Am I missing something?

The wait begins (estimated 8-12 weeks)

Reply With Quote

Reply With Quote

Bookmarks