I recently finished a project: pillar mounting and bedding a Boyds stock to an Axis Heavy Barrel .308. I think jpdown (posted above) gave a good point of advise about carefully drilling the Boyds stock for the pillars. Use a good bit and drill press if possible or the laminate wood could crack and take small chunks out. I can cover it in a little more detail:

I chose the Savage Axis Heavy Barrel in .308, and chose a Boyds Varmint Thumbhole. Started out drilling the front and rear mounting holes to fit the pillars. Both pillars are DIA .375 OD, DIA .25 ID. The front pillar started out at .5 inches long and cut down to .42 inches to fit this particular stock. The rear pillar was 1 inch long cut down to .95 inches long. The length can vary from stock to stock, so it is a good idea to custom cut your pillars.

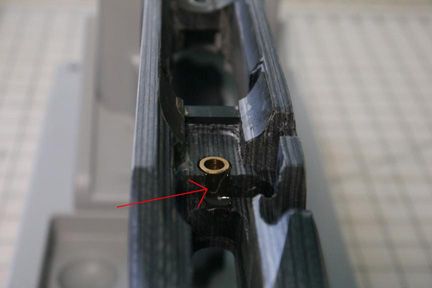

Front Pillar

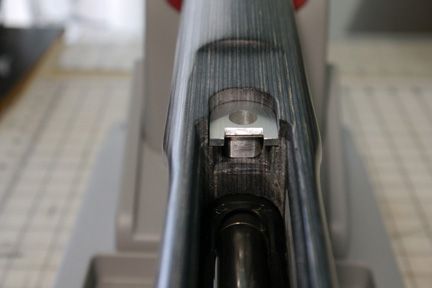

Rear Pillar:

The front pillar is stainless steel, but the rear I experimented with bronze. The bronze was easier to trim down, and is working great so far.

After inserting the pillars, I bedded the stock.

Front Bedded

Rear Bedded

You can see where the laminate was chipping off during the drilling procedure. I went ahead and mounted the pillar, then used epoxy to seal and reinforce the gap in the laminate wood.

This is where I did something a little different. When I was applying torque to the front mounting clip (plastic piece), it was cracking apart. The plastic trigger guard cracked apart also. I had already replaced the trigger guard with a metal trigger guard and decided to get rid of the plastic in the front. I replaced with an aluminum front mounting clip. First I 3D printed the part to verify fit and function, then CNC milled the front clip out of 6061 aluminum. If you notice, I did not include the insert piece (a part of the plastic piece) so the aluminum piece is optimized for pillar mounting.

The aluminum piece fits in the same mounting provision and allows you to apply proper torque to the front mounting screw. Now it is all metal to metal, so you can torque it down for a solid fit.

It also allows normal function of the magazine to clip on.

It turned out pretty solid. So, if you want to pillar mount the stock, be sure to take your time drilling out the mounting holes on the stock, custom cut your pillars, and get rid of the plastic if possible. Be sure to double check the depth of the mounting screws or you won't be able to cycle the bolt. If there is interference, try using a thin washer to give more clearance.

Reply With Quote

Reply With Quote

Bookmarks