Good thing Vortex has a great warranty.

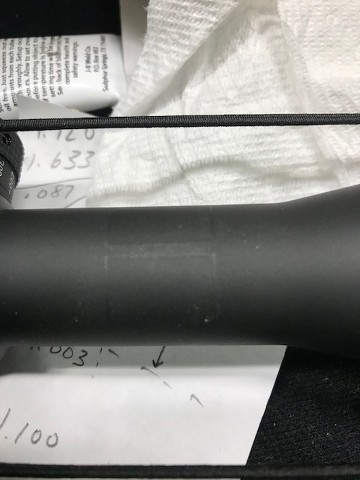

Well, crushed might not be the right word, but it's dented for sure. I bought a Vortex Diamondback HP scope and mounted it on my Savage. I used Warne rings, like I have done with a lot of my rifles. Warne recommends you torque the rings to 25 inch lbs. I even have there torque wrench, which is specific for their rings and will not allow torque over 25 inch lbs. Well, I read somewhere or saw something on the internet (don't remember) about Vortex recommending only 15-18 inch lbs on their rifle scopes. I took the rings off my scope and sure enough, the scope tube in dented where the rings were. This has never happened to me before on any other scope. The scope is on it's way back to Vortex due to their VIP warranty. The rep also confirmed, no more than 15-18 inch lbs. I admit, I do not look at the scope manufacturers mounting instructions anymore. I have mounted so many scopes that I just assumed they were all pretty much the same. So I went back and looked at the instructions and no where does it say (other than on their website) to only torque the rings down to 15-18 inch lbs. The Warne rings are steel ring and 25 inch lbs might be high, but most aluminum rings are at least 20 inch lbs and the DNZ mounts are also 25 inch lbs. I just feel that Vortex should mention this in the instructions and put a warning label (that can obviously be removed) on the scope. It would have saved me the hassle and shipping costs. Just my personal opinion.

Good thing Vortex has a great warranty.

VIP warranty is a good thang..

Perpetual Optimism is a force Multiplier....

Now, install one of those great warranty scopes on a hard recoiling gun and see how well their recommended torque settings hold the scope.

Redfield rings will do the same to Nikon aluminum tube scopes. ;-)

From what I can tell it doesn't hurt a thing - merely cosmetic. Most shooters who don't remove a scope would never know.

Well it does make a difference, and it could affect the scope by screwing up the erector system inside, thereby affecting the ability to make adjustment changes. Ive had first hand experience with this and the scope tube hadn't even been dented. Tighten those rings down enough to hold the scope and you wont be making elevation changes with that scope. Call the factory and they will tell you to loosen the rings to 15# of torque which wont hold the scope on heavy recoiling guns.

Unless the wrong sized rings were used a "normal" tightening wouldn't be able to crush the aluminum outer tube enough to hamper the movement of the inner element tubes for windage and elevation adjustments.

Did the original poster mic. the "crushed" tube to see how much it had been swadged? The inside dimensions probably weren't impacted at all from looking at your image.

No I didn't mic the crushed tube, but when the rep from Vortex recommended I send it in, I did. Here is the video I watched on the Vortex website. https://www.youtube.com/watch?time_c...&v=p3yJ2JF9L5E

This is what made me question if the crushed tube would cause a problem. It's winter right now and I didn't plan on shooting this rifle until the weather got better. I just figured it would be better to send it in and have a qualified tech take a look rather than try to guess if it was okay.

i don't doubt they will honor it - because it is marred and they have a great warranty.

But I think you would not have noticed any performance issues.

Their "Precision" rings as they recommend for the Diamondback are aluminum as well. Aluminum on aluminum won't leave marks (or are less apt to, anyway).

Personally, I'll take the marks left by Redfield or Warne steel rings on aluminum tubes. I like steel bases and rings on any centerfire. And prefer steel rings on everything. I've buggered more rings by pulling threads out with the clamping (steel) screws and that WILL cause a problem.

The key word being (NORMAL).

A 30mm tube, is a 30mm tube and 30mm rings should work regardless of brand selected.

The fact is their scope wont function if the rings are tightened beyond the limits they suggest.

And those limits aren't enough to keep the scope from moving in the rings with heavy recoiling guns.

Regardless of any good features the scope has, and regardless of the wonderfull warrenty, it still dosent perform as for dialing elevation which many people do.

This 5.5" x 1.5" tag was attached to the top turret of my HSLR when I took it out of the box...

Attachment 4341

Maybe they forgot to put one on your scope.

Not implying anything just sharing what was attached to my scope. Bought my HSLR from Cabela's during the black Friday sale and was delivered to me Dec 1st. I have no idea why there wasn't a similar tag on your scope.

It's all good, Vortex is taking care of you and that's what matters.

If you've read what ive said carefully, ive not actually trashed Vortex scopes.

I have no doubt that for most people they make a fine scope choice.

I also know they make other models i have no experience with.

I of coarse have my own opinions, which are based on my own experience with just one scope.

The tag shown is obviously a rather new item, as it was not included about 4 years ago when our scope was purchased.

They should also go further in my opinion, in stating on the tag that those settings might not suffice with heavy recoiling guns, because in fact they don't.

We could debate ways which might help in doing that, but that wouldn't address the issue, which is a thin scope tube.

So which Vortex model are you referring to and what is their specifications for tube wall thickness?

I'm a Vortex fan and am just curious. I am always open to learning info about the things I own and like be it pro or con.

I currently have the Viper line and am putting it on a 300 Win Mag and expect to use a torque driver along with some rosin under the rings. I hope my tube's not gonna crush and the darn thing will stay put under recoil.

When searching for best scope for 300 Winmag, I notice the top 3 sites Google returns all include at least 1 Vortex scope in the top 5 recommended choices.

https://www.swggun.org/best-300-win-mag-scope/

http://www.reloaderaddict.com/best-s...r-300-win-mag/

https://manlygearreviews.com/optics/...r-300-win-mag/

So, I'm just curious about the exacts you're alluding to..

I believe the torque specs are pretty universal (15-18 in-lbs with 15 being most suggested). Scope tube crushing isn't a new phenomena unique to Vortex (Just read about a Swarvoski crushed with Warne rings).

I'm glad I found this thread. I need a torque wrench instead of elbow grease...

The scope i referred to is a Vortex Viper 6x24, purchased from Euro Optic in Montoursville Pa.

Where it was purchased has no bearing, other than they were the ones who had the Vortex rep call me within hours after i had complained to them.

I did not own a torque driver at that point because up to that point, i hadn't needed one.

Now is the fact that we do (sometimes) need them now, due to what we have been doing wrong? or is it due to the (dumbing down) of what we deal with in todays society?

I been doing it wrong. I have never seriously considered purchasing a torque wrench for mounting a scope before now. I have never heard of rings crushing a tube. Then after researching today, it's not a new issue. When reading about properly mounting scopes, these are the reasons why it is suggested. The specs aren't unique, most all scope ring and scope manufacturers recommend a specific torque and using a wrench to verify. Those specs for the vast majority are the same.

Perhaps my old Redfield 3-9x40 from the 1990's would have never been crushed, but that's not what I'm dealing with. I've read about the crushing of some pretty expensive scopes today. I'm also about to order a wrench and follow suggestions.

I have always used a torque wrench when mounting scopes. I always followed the ring manufacturers torque spec, mainly because I never had any specific torque specs from the scope manufacturer. Knowing what I know now, from this point on, if there are no torque specs form the scope manufacturer, I will call and ask before I mount any more scopes. I chalk this up to a learning experience and I'm very thankful the scope is warrantied.

I'm not about to get into any debates over torque wrench use. If a person feels they should be required equiptment fine with me.

As for new quality scopes requiring their use, i cant say, because i haven't installed that many newer scopes.

That said, i wouldn't take it to the bank that price, or even brand name correlates with top quality.

I don't personally think we should need to invest in specialty tools in order to mount a scope.

A proper fit screwdriver is all that really should be needed in my opinion.

And i know for a fact that some very well known gunsmiths install the scopes THEY SELL, just that way.

I guess the bottom line is, we mostly buy what we can afford, or feel is adequate for our use.

And then do what we must in order for the thing to function properly.

In days past (1990's included) the practice was to use steel rings on steel scope tubes. I've never yet crushed a Leupold or even a Weaver with Redfield, Leupold, Sako or Weaver steel rings. Marred the bluing off some, to be sure.

Now aluminum tubes are the norm, but I still prefer steel rings. I don't like steel screws in aluminum threads. Just a personal thing. My 1/4" torque click wrench (Tekton - $35ish) only goes from 20 to 200 in/lbs. Maybe that's why I don't have luck with aluminum rings? But, so far, my scopes don't seem to be effected.

https://www.tekton.com/1-4-in-Drive-...h-20-200-in-lb

I just looked and they also make a 10 to 150 ft/lb wench for $49 (cheaper at distributors) - US made as well.

https://www.tekton.com/1-4-inch-driv...rench-trq21101

"They couldn't hit an elephant at this distance." Last words of Gen. Sedgwik

Bookmarks