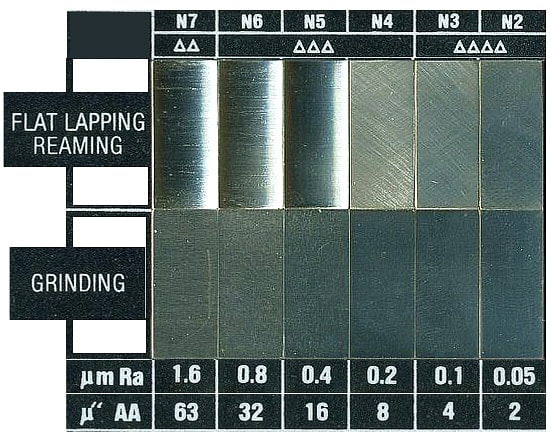

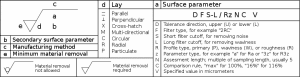

The surface finish of the lugs offers little bearing on Bolt Lift. Itís made increasingly worse, due in part, to the timing not properly synced of the Action/Bolt Head Lugs in front & the Camming Lugs in the rear of the Bolt Handle/Rear Baffle, aiding Primary Extraction. The relationship of function among the Trigger/Sear system, Bolt Release & Firing Pin spring account for some of the excessive Bolt Lift as well.

When you mention the Thrust bearing type lift kit, if you have the adjustable style Firing Pin assembly, I recommend the style using a single steel or ceramic bearing ball on a hardened disk. Itís all about Coefficient of Friction. I this case,

less is

more. No need to overthink anything. Or try to reinvent. All the tricks are readily available on bringing bolt lift to within very acceptable limits. You are correct to pay attention to the Bolt. And yes, a T&T job may be beneficial. We have mixed reports: Some claiming complete curing of their harsh bolt lift & now having a quite Action. Some who claim it was a complete waste of money, and their Action feeling identical to how it was before sending for the T&T. It seems to me that yes, some 110ís may benefit from this, if in fact, the heavy bolt lift is because their 110ís front/rear Lugs are very far out of sync! Other 110ís arenít always terrible to begin with. And having a T&T performed isnít going to be Earth shattering if any discernible difference. Itís straightforward on how to check the timing on your own, before choosing to spend the money. Video below illustrating checking Timing on a Rem 700. The Savage 110 is quite similar. This can felt especially when you have a bare Action & Bolt assembly. Timing can be both visually seen & felt by the hand like this.

https://www.youtube.com/watch?v=szy4HBg3q80

Reply With Quote

Reply With Quote

I am wondering if going to 6BR instead of another caliber. Man it's hard finding "good" brass. I spend over 1.5 hours per day looking!

I am wondering if going to 6BR instead of another caliber. Man it's hard finding "good" brass. I spend over 1.5 hours per day looking!

Bookmarks