Dear Savage Community:

Here's my current attempt on Axis Magnum conversion as I had been slowly collection parts and reading on this subject, especially after reading Dr. Thunder88's "MAxis" post back in 2016.

http://www.savageshooters.com/conten...-s-Maxis-Build (Thank You So Much Dr. Thunder88 !)

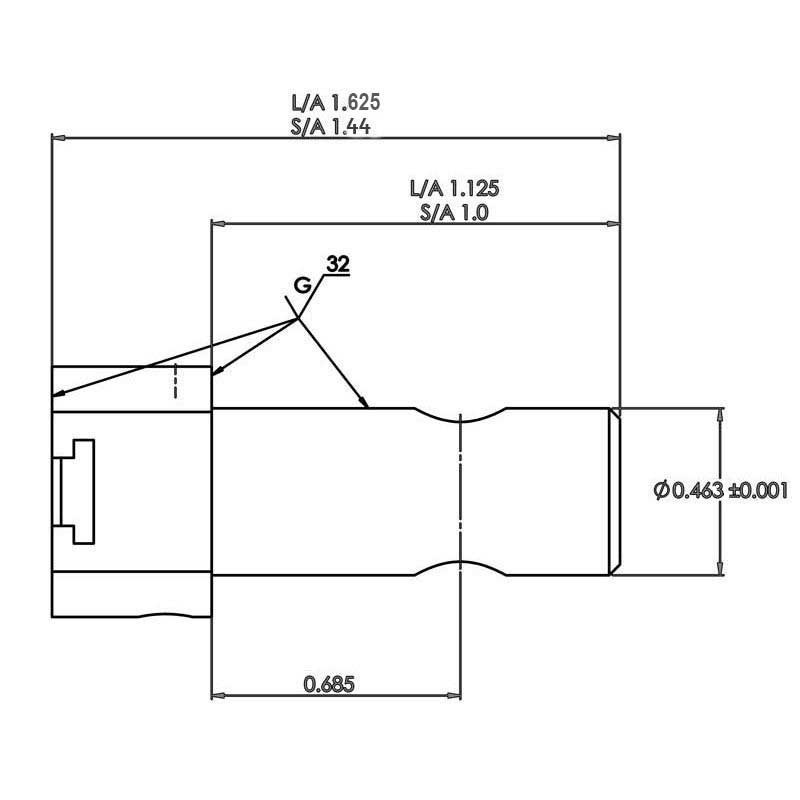

I ordered the Long Action Magnum Bolt Head from MidwayUSA, savage part# 103960. . Upon receiving it the bolt lug measure a little under half inch, which as compare to the axis bolt lug it is 0.44 inch. In addition, as Dr. Thunder88 had pointed out, alone with a video, the Magnum Bolt Stem is too long and need to grind down to around 1 inch in length.

Last night I finally got around to performed the magnum bolt head's stem shortening. I continue to check back and forth with the Axis firing pin, until I achieve 0.05" protrusion. However, in order to achieve the desire firing pin protrusion, the grinding of the magnum bolt head's stem went under 1" in measurement.

Upon assembly the bolt with the magnum bolt head that been worked on, measurement of the firing pin protrusion is only at 0.025 inch at this point. Turns out the Firing Pin Cocking Pieces has bottom out in the bolt body slot, and prevent the firing pin from making the 0.05 inch desired. Consider the fact that the magnum bolt lug measures at around 0.49 inch thickness, while the Axis bolt lug is only 0.44 inch...

At the moment I am considering this solution to resolve this:

Grind down slightly on the bolt body's slot, where the "cocking piece pin" bottom's out and is currently preventing the firing pin the final travel/protrusion.

My question is would this create other issue if I take out around 0.08 inch and allow the cocking piece pin moves deeper upon firing? I have read that at 0.035 firing pin protrusion is enough...

https://photos.app.goo.gl/DRCvY1aekZayhHv8A

Please excuse my ignorance on the technical aspects, as I am still rather new on custom works, learning and digesting info, articles, advises while making hands on approach. Sincerely Many Thanks!

Reply With Quote

Reply With Quote

Bookmarks