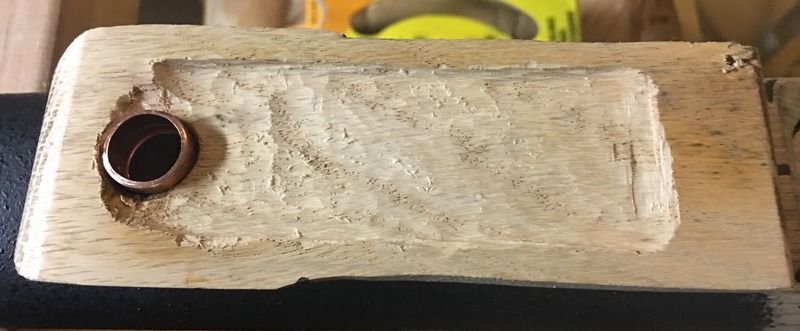

So the bedding was taped off. The rest of the finish blasted off. The rifle was cerakoted in Sniper Grey and Graphite Black. The stock was sanded to 320 grit. I cerakoted the stock in graphite black base with OD Green and Sniper Grey sponged on. This was my first time sponging cerakote and my first time cerakoting a wood stock. I made a custom adjustable Kydex cheek piece. Learning notes to everybody, I heated the stock to 180 degrees for an hour to make sure no oils leaked out of the stock prior to cerakoting. After coating the stock, it baked at 180 for 2 hours. During that time, the stock shrunk some and the pillars retained a lot of heat, which caused the bedding to crack next to the pillars. Also, where I bedded in the bottom piece, there were visible cracks that weren't present before cerakote. I had to reapply bedding to reinforce the cracks. Overall, it turned out.....ok. I'm not impressed. It's definitely not my best build. What would you have done differently.

Reply With Quote

Reply With Quote

Bookmarks