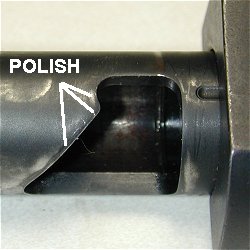

Take your bolt apart and check everything that moves for burrs or any galling. The used 116 I just bought had some serious cocking problems that I was able to clean up by polishing the inside of the bolt tube and the extractor tube, removing some burrs from the hole in the firing pin assembly and cocking button. Made a big difference. It now cocks smoothly like my 111. Due to the design, it is never going to be as smooth as some of the other bolt actions, but if you clean it up and lube with just a light coat of oil, it will help. Especially check the cocking ramp in the bolt body.

Reply With Quote

Reply With Quote

Bookmarks