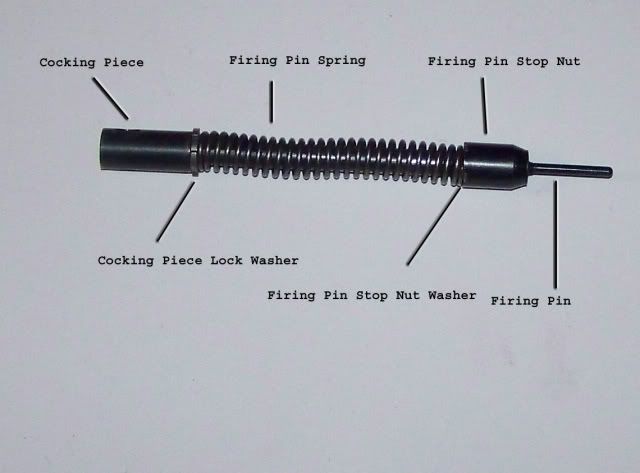

I don't have a stepped firing pin assembly to assist you with, but did you measure the spring with the cocking piece in the cocked or uncocked position? You can back the bolt assembly screw off, cock the cocking piece, and then tighten the assembly screw and see where your measurement ends up with it in the cocked position.

Reply With Quote

Reply With Quote

Bookmarks