You don't like using case gauges Like wilson sinclair? Hornady LnL?

For those loading the 7mm wsm how are you measuring the distance from the case base to the shoulder?

In other words to set my shoulder back .002 how are you measuring this?

You don't like using case gauges Like wilson sinclair? Hornady LnL?

Sorry to not be clear- not asking how is this done but interested in how YOU are measuring this.

What tool/method are those loading this round using, pros/cons etc.

If your question is with regard to not being able to chamber the case, then yes the shoulder might require bumping or setting back.

An easy fix is to purchase a set of Redding competetion shell holders. Follow the instructions which will tell you to start with the

lowest number shellholder and resize the case. If it dosent chamber, go to the next size shellholder untill it does.

You could also speak with a tech at sinclairs who could advise you.

Doesn't camming over have the same results.

Dean

RUMs are like woman in Stiletto heals, you know they are going to put you in the poor house, but that has never stopped anyone from pursuing them.

I use the hornady cartridge headspace gauge bushing to measure the shoulders on my cases.

No-again this seams to have gone off the tracks.

As a general rule in reloading it is favorable to resize necks to x, a measurement that allows proper tension without overworking the brass.

At the same time one might want to minimally size cases to where they have a consistent presence in the chamber, a .002 bump is common.

For those who are loading 7mm wsm cases which dies/tools/methods have you personally found effective for this procedure? What ancillary steps have you found helpful? What have you found superfluous?

LongRange- Thanks, which bushing are you using?

I dont shoot a 7mm WSM but i use redding body dies to bump the shoulders back and the tool above to measure.

What is the parent cartridge to the 7mm WSM?

You would have to varify this with hornady or someone that knows more about the 7mm wsm but it looks like you can use the 300 wsm bushing which is E-420.

I use a socket from my tool drawer that fits over the neck and a pair of calipers. Measure a fired piece then adjust the dies to get 0.002" bump.

Low tech, but a $10 socket set from harbor freight will work with about any case. Same basic principle as the Hornady headspace bushings.

"Muzzle velocity is a depreciating asset, not unlike a new car, but BC, like diamonds, is forever."-German A. Salazar

Again, I use my Stoney Point (Hornady) tool.

In this instance a 280 with a .375" bushing on the shoulder. The bushing on the casehead is counter bored .100" deep so the actual length is 2.099".

But as Geargrinder said, you don't need a setup like I use, a socket, cartridge case or anything that contacts the shoulder about midway will suffice. You're only looking for a before and after number.

Bill

Each morning eat a live green toad, it will be the worst thing you'll have face all day.

For me, the most important part of setting H/S is to ensure the case is fully fire-formed. Quite often this doesn't happen until the 2nd or 3rd firing. Indicated by the point that a fired case shows resistance to chambering and thus, reaching maximum growth in your particular chamber. Adding H/S by bumping a shoulder back on a case that had a less than max powder charge only adds to work hardening and increases actual H/S needlessly. Using a F/L sizing die will push your shoulder forward and can be used to get the shoulder set to that "just right" feel when chambering an empty cartridge. Any shoulder measuring method that gives you a before and after reading will do the trick. Like GEARGRINDER I've used sockets and I've used empty, de-primed pistol cases as H/S gauges before todays tools were commonly available........ Ingenuity is the mother of invention :)

Sorry to not be clear- not asking how is this done but interested in how YOU are measuring this.

What tool/method are those loading this round using, pros/cons etc.

I think I understood what you asked the first time. The case headspace dimension from the base of the case to a datum somewhere on the neck is the dimension you want to measure to allow you to make an informed shoulder bump of .002. after firing. Allong the lines of billPa post and consistent with my first post. Use a gauge that measures it like the Hornady Lock and load case headspace measuring tool.

It does not matter if it is a 222 or a 338 lapua. This tool will tell you what you need to know.

The wilson I mentioned

requires you to put your case into the gauge and measure to the base of the gauge to the base of the case or from the mouth end of the gauge to the base of case and get a dimension. When you size the case you put it back in and measure the change. Dillon and others make the same thing.

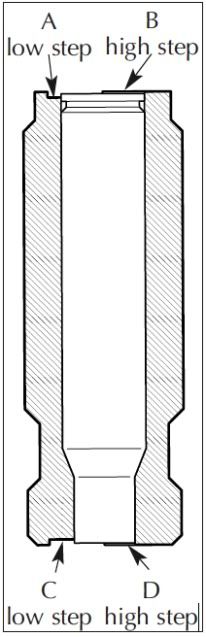

This is a drawing of a sinclair but works the same.

Last edited by Robinhood; 12-18-2014 at 12:00 PM.

Sorry, you asked for pros and con's. The Hornady is a tool that gives you a reference. As the tool wears the numbers may change slightly. It has 4 or five sleeves for different cartridges and is very versatile. The also have other inexpensive collars for each caliber you can use with the same red base. You can measure your bullet ogive lengths with those. Good tool for the investment.

The chambered Wilson/ Sinclair case heads pace gauge is designed for only one specific cartridge. If you look at the base of the gauge in the picture above you see a relief in the face. That lines up with the Saami min on the bottom of the relief and if the case lines up with the top it is at Saami max. Also good stuff and usually a quality tool to have. It is for obvious reasons not versatile. It is however very precision and will always read the same.

As an afterthought, I took the liberty to find Hornady's bushing list. You would end up using "C"

Great replies thanks, geargrinder that's a pretty clever idea!

Bookmarks