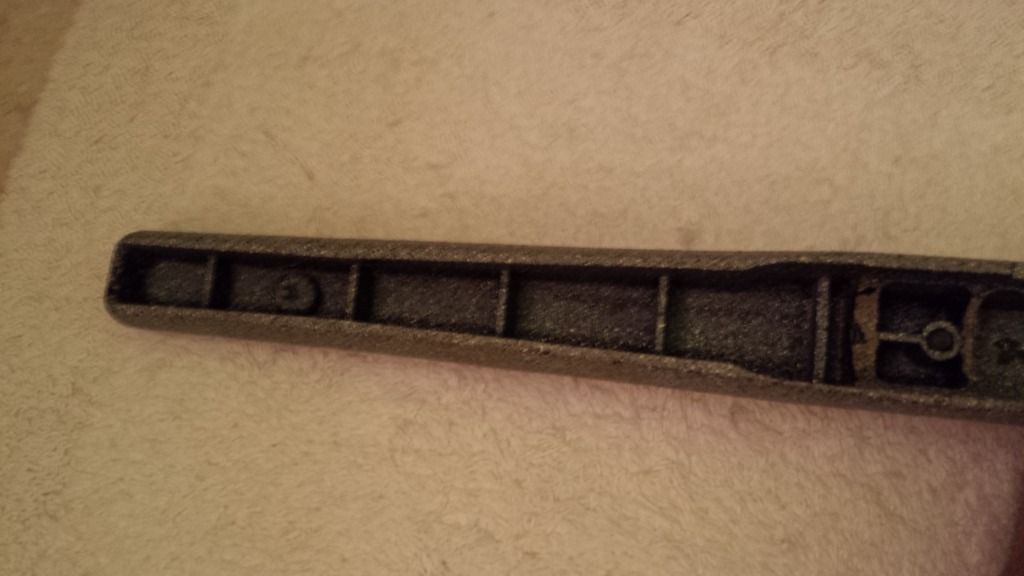

I started working on the inside, removing paint and contouring a little the fluting on the grip, which is very pronounced and not comfortable. I have done a lot of wingshooting and clay shooting and know the feeling I like when shouldering a gun. Drilled some holes on the plastic and removed the plastic "bridges". The stock did not look like an ice tray anymore.

Then I got to the fun stuff. I found an aluminum arrow shaft for $0.99.

1/4x28 bolts that I cut the heads off, Devcon epoxy and Aluminum Pillars from ebay http://www.ebay.com/itm/Gunsmith-Acc...-/191127055391

It comes with "instructions" (not very good) and epoxy in the double syringe, the guy also sells pillars without the kit. They are lightweight and very textured exterior, which shows in the pic below. They are contoured, though I may dremel some of it off for a "mo'betta" fit, and still use bedding compound and skim bed after installation.

This is where I have marked the stock for installing the Grovtec flushcups and swivels on the side (for carrying flat).

I am not sure if I should do the swivels at the same time I complete the bedding and forearm, before, or afterwards.

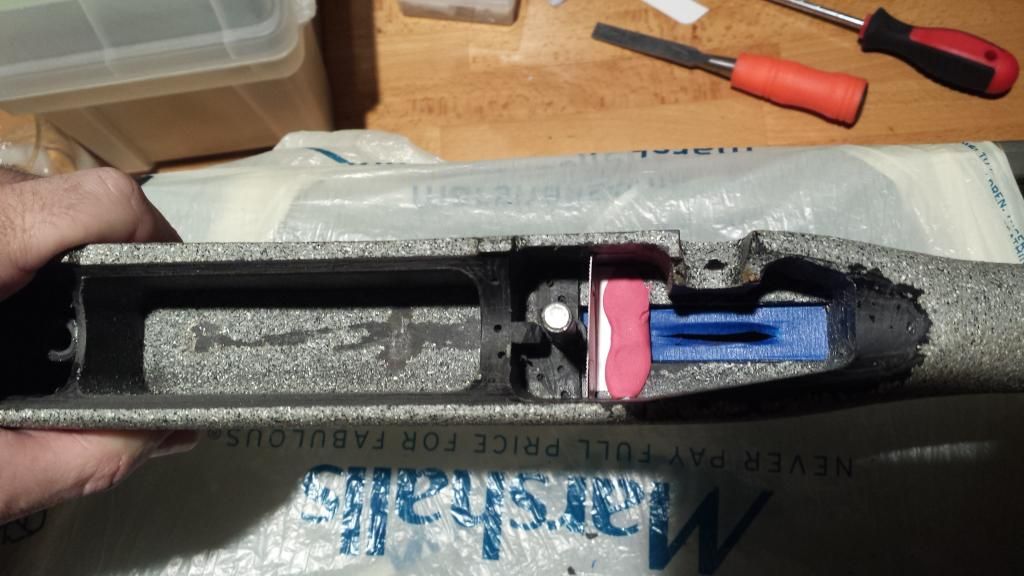

This is the arrow (cut) being laid in the forearm. The rods go into the recoil lug area (don't affect lug fit). Thinking back I should have gone all the way back into screw area "well", but it was hard to drill and didn't think about it at the time. The shorter one is to allow room for the swivel cup.

Partially bedded arrow and front well.

Looks rough because I will do skim bedding, free float barrel, but bed forearm appropriately.

Reply With Quote

Reply With Quote

Bookmarks