I'd guess conditions played a big factor, along with a factory 22-250 barrel in a Tupperware stock. Five groups aren't a good indicator of accuracy, but a <MOA average doesn't seem bad to me.

The title says it. Each of the last 5 times I have taken it to the range the accuracy has gotten worse.

Gun:

Savage 12FV 22-250 4months old. Barrel broken in per Savage recommendations

Vortex Viper 6.5-20x44 scope Parallax properly adjusted

Leupold rings

Plastic NON Accustock

The gun has never been dropped banged or jarred in any manner. The crown is factory perfect. The cleaning rod is used from the breech with a rod guide.

Ammo:

cases trimmed to the same length

FL sized (tried neck and collet sizing but neither is helping at this point) The groups listed are all FL sized cases.

cartridge length all the same and verified each length by measurement on the ogive.

trickle weighted the powder charge, same powder out of the same can...same primers...different lots.

Same bullet different box

Always used the same front and rear sand bags...off of the same concrete shooting bench at the range

No wind to speak of.

Holding the rifle exactly the same to the best of my ability.

Always allowed the barrel to cool to the same temp (roughly) before the next volley. I am working up loads with a warm, not hot, barrel as this is a Prairie Dog gun and will be fired warm to hot more than an Elk gun that will be fired once from a cold barrel.

First started working up loads and got to where I was getting (12-18-13) 1.1" 5 shot groups at 200 yds with 3 of the 5 at about .257".

Needless to say I was happy and just needed to try to get rid of the two flyers ruining the groups.

This was all before Christmas.

Enter 2014 and the Grinch must've swapped rifles with me.

5 shot groups are listed as follows

12-18-13 1.1"

12-19-13 1.4"

1-2-14 am 2.14

1-2-14 pm 1.55"

1-11-14 2.25"

Between 12-19 and 1-2 I tightened the action screws to the proper torque.,,,they were about 25in/lbs and spec is 35 for the plastic NON Accustock. Group opened up an inch.

Between 1-2-14 and 1-11-14 I removed all of the copper fouling using a nylon bristle brush and verified a clean patch before figuring I had all of the copper removed. I did this as it "looked" as if there was quite a lot of copper built up in the rifling. I understand it can take a while for the rifle to settle back in after removing all copper. In the process of trying to get my accuracy back with the specific recipe I was getting my best accuracy with I have been shooting other recipes of the same bullet and powder but varying weight and length looking for that "sweet" spot.

I have rechecked the scope mount screws and they are all tight.

I annealed all of the cases today verifying proper temp evenly applied all around the neck and the base not getting hot enough to change the hardness. These cases have NOT been fired yet since the annealing but are used cases.

Each of the4 times I go out I shoot between 15 and 45 rounds depending on how many recipes I am trying.

I have tried everything I can think of and the groups just get worse.

I am going to try the annealed cases and have a buddy who is a very good shot ( he out shoots me with my own guns from time to time) shoot it and see what happens.

I understand I have a couple things to check out yet but welcome any new ideas.

Thanks

Darrell

I'd guess conditions played a big factor, along with a factory 22-250 barrel in a Tupperware stock. Five groups aren't a good indicator of accuracy, but a <MOA average doesn't seem bad to me.

I would say we found the problem right there. Your not getting the hard carbon out, copper is the least of your worries. If you keep going this route you will soon find that the bullets will start to keyhole. I find that most accuracy problems come down to one of two things. Bad scope, and improper cleaning.

To start, copper is the easiest thing to remove and it can be done with plane old ammonia bought at a grocery store. The thing is where accuracy problem lie is in hard carbon. The black soot that comes out when you fist run a patch through is not hard carbon, it is soot. Unless your using a bronze brush, and good cleaning solvents you will never get hard carbon out. Think of hard carbon like this, it is partway a diamond. I recommend you clean the barrel with Remington 40x cleaner, or some other form of mild abrasive like JB bore paste. Use a good solvent like Butches, Sweets, Shooters choice, and a bronze brush. After the barrel is clean you will have to shoot a few shots to season the barrel back in. I found that a lightly fouled condition is where factory Savage barrels preform their best.

Moving on just because a scope is new, or a certain name brand doesn't mean it is not bad, and just because it has not been bumped doesn't mean that it cant go bad. So keep that in mind.

Good luck

82boy

I have thought about the scope. It is still an option. Unfortunately neither I nor my friends have 30mm scope I can try in place of this one.

I didn't start doing any heavy and hard cleaning until I noticed the accuracy slumping off. I usually use a brass brush with Hoppes #9. I used the nylon brush with Sweets 7.62 as (I believe) the copper in the brass was dissolving and I wasn't getting a accurate color on the patch.

Where does this hard carbon accumulate? does it stay on top of the copper fouling or is it embedded within the copper? I understand some copper is good, but, as with all things too much can be bad.

Will cleaning with Hoppes #9 and a brass brush be adequate for getting the hard stuff out?

THanks

Darrell

Well I hate to burst you bubble but no, it will not do it. Hoppes at one time was a good cleaner, but the stuff that is out in the last 20 years is about as good as water. Use Sweets and a bronze brush, immediately after brushing rinse your brush out in rubbing alcohol, or spray the brush out with carb or break cleaner. Sweets is a strong ammonium based solvent and will eat brushes. Sweets will do light work on hard carbon, but I think that it is too late and you need something abrasive. Hard carbon will accumulate throughout the barrel, and usually is thickest near the chamber. Hard carbon will attach itself in microscopic pores in the steel and copper will attach itself to it, and make layers.

I prefer JB bore past and scrub all of my barrels with it, at every 100 or so round counts, but most people cant find it or want to order it, it is a brownells product. For this reason I tell people to go to Wal-Mart and buy Remington 40x cleaner. It is the same product as JB bore paste, just has a different carrier. This product was developed by Ferris Pindell, (Benchrest legend, and renowned firearms expert.) and he recommended this product. I find that 40x cleaner is mush more aggressive than JB, so use it with care. A tight fitting patch worst best, and burnishing strokes (Short strokes back and forth.) will do the job. Run a patch or two of it, and then clean out with solvent and a brush.

Something else hard carbon will appear dark brown on your patch's. JB or 40x cleaner will always come out black. There is some other products to remove hard carbon, like bore tech carb out, never tried it, but reports it works good. There use to be a product made by General motors, called GM Top Engine cleaner called TEC, it was a wonder thing to remove carbon, but it is no longer made.

82boy

Well that definitely isn't what I wanted to hear. I am pretty leery of using anything abrasive in my barrel. Could you see hard carbon build up with a bore scope? I will do what I have to but something abrasive I think I need to verify that hard carbon is the issue.

You mention you use it every 100 rds or so. What tells you it's time to use the JB paste?

Darrell

Yes you can see hard carbon buildup in a good bore scope.

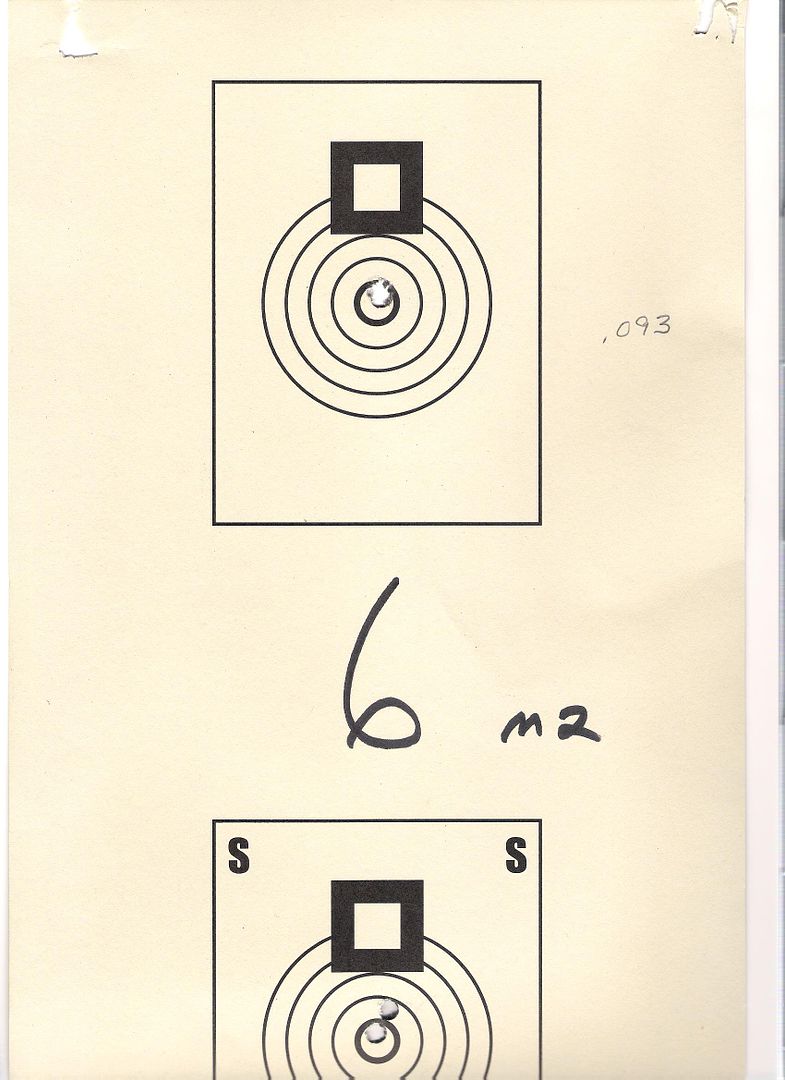

How do I know it time to use JB? Answer is feel of the patch when I push it through the bore. When the patch is "grabby" its time to use JB, after cleaning the patch will glide through. I understand about being scared to use an abrasive cleaner on your expensive barrel, but I have yet to see where it hurt anything. I have seen many PPC barrels go 4000+ rounds with regular use. Need a bit more convincing? Here is a target I shot in a match last year. This is 5 shots at 100 yards, under 7 minute time limit. This barrel has around 700 rounds on it and has been cleaned with JB close to a dozen times. I think if it was hurting the barrel it would not preform like that.

82nd Boy's advice with jb paste is spot on I use it quite often to clean my barrels also, never had a problem

Quote: Between 12-19 and 1-2 I tightened the action screws to the proper torque.,,,they were about 25in/lbs and spec is 35 for the plastic NON Accustock. Group opened up an inch.

Along with the possible carbon issue, this caught my attention

Jack

Check front action screw, it could be touching bolt head. Coat outside of bolt head with magic marker, cycle action a few times & check for rub marks. If there are rub marks shorten screw.

What I do is take a patch that wont fit down the barrel like a 30 cal patch and cut the corners off.Then take JB,Iosso<40x cleaner and saturate the patch and insert till you feel it stop with light pressure.Then turn the rod over and over at least ten times,remove and do the same thing with a clean patch,borescope.If it isnt metal showing,do it again and look at it,if the barrel metal is showing you have removed the carbon ring in the chamber which is the most common cause for loss of accuracy.Also do it to the barrel like 82 boy suggested.The abrasive is so mild it wont hurt a thing.It is non imbedding meaning it will come out of the barrel easily with patching and brake clean(crc brand is the least stinky to use) and get the rags and anything saturated out of your house when you are done with a well ventilated area being a must.You can also use a 22 cal brush with a patch wrapped around it with the JB or which ever you use to really get the carbon out.Good luck.

Willing to give back for what the sport has done for me!

Looking through your post again, this little segment bothers me. Are you shooting over wind flags? How do you know there is no wind? Some of my worse groups was shot in the calm. I hate calm and choose not to shoot in it if I can. I would rather shoot in 20mph winds, that are consistent.

One last thing looking at your groups, the average is 1.688, these are all at 200 yards. Why don't you shoot more groups, and just 1 a day? What are you expecting? You say your happy with the 1.1 group, so basically you had two bad days. I am reading into this, and is this a new gun that only has been fired a few time's and your developing a load for it? I find it is always good to shoot with someone else that way you can compare what your doing to what they are doing. If they shoot big, and you shoot big it is the conditions. Was there drastic temperature swings between these days? I am starting to re-think this and say the gun is just out of tune.

As far as removing the carbon ring I do the same thing as Tony Boyer does, I take a short segment of cleaning rod, and place a next caliber bigger bronze brush on it, I insert it in the neck, and twist it around a bit.

Screw torque "within spec" and screw torque that actually produces the smallest groups can be two different things. Check out Stan Pate's article on this topic. I did, and found that the precise number varied a fair bit between otherwise identical rifles and stocks.

http://www.accurateshooter.com/techn...torque-tuning/

This kind of experimentation can be a bit laborious, but it's been worth doing for me anyway...

Also, I would second the advice regarding JB bore paste. I've had great experience with it and the foaming bore cleaner. Butch's works well too to remove copper. I have banished bronze brushes from my garage and now use nylon brushes from Brownell's/Sinclair. Your mileage may vary.

And, I've yet to find anything that doesn't improve with Kroil. This all might be overkill but it helps scratch my OCD itch.

Good luck.

Just posting up results for future searchers in hopes this helps someone else out.

Turns out it was the scope. The objective lens cell was loose. It was tightened by the manufacturer and sent back to me.

Took it to the range today for a sight in session and recorded these groups at 200 yds.

.436,

.485,

.500,

1.4 oops

Darrell

Good to hear you figured it out!

Sorry to hear vortex let you down

Bookmarks