Originally Posted by

82boy

To start not all bushing dies are created equal, I find that the one popular company that mass produces them makes the worse offenders, as they are sloppy built, with the bushing rattling around, and that they are improperly made, and need modification to properly size the case.

Now with all that said moving onto the lee collet dies, if what your saying is truthful, you would be the first person I have ever herd of that is measuring there end product, and not having problems. On the other side of things, with annealing, running through body dies, and everything else, it is just WAY too much work. Going further, I find that neck sizing and using a body die prematurely work hardens the brass, and that with a properly set up FL die the brass last longer, with less work needed. I have also done both methods of neck sizing, and FL sizing and have found that FL sizing makes a round more accurate, that is repeatable. I have found that the chances of having an unexplained flyer, is much greater with neck sizing. My experiences with the Lee cullet dies, have not bee favorable, and running the rounds over a concentricity gauge, I could never produce a round that had good run out, let alone by design of the collet die, it produces a donut, with repeated use. It could be that your fixing these problems with annealing, but I don't anneal my brass. With that added, I shoot competitive Benchrest, and have shot many match's all over, and I have never seen or hear of anyone of them using a lee collet die. I have asked many other accomplished reloaders/shooters, and never found any of them using a lee die. For many it is a running joke, asking someone if they use a lee die.

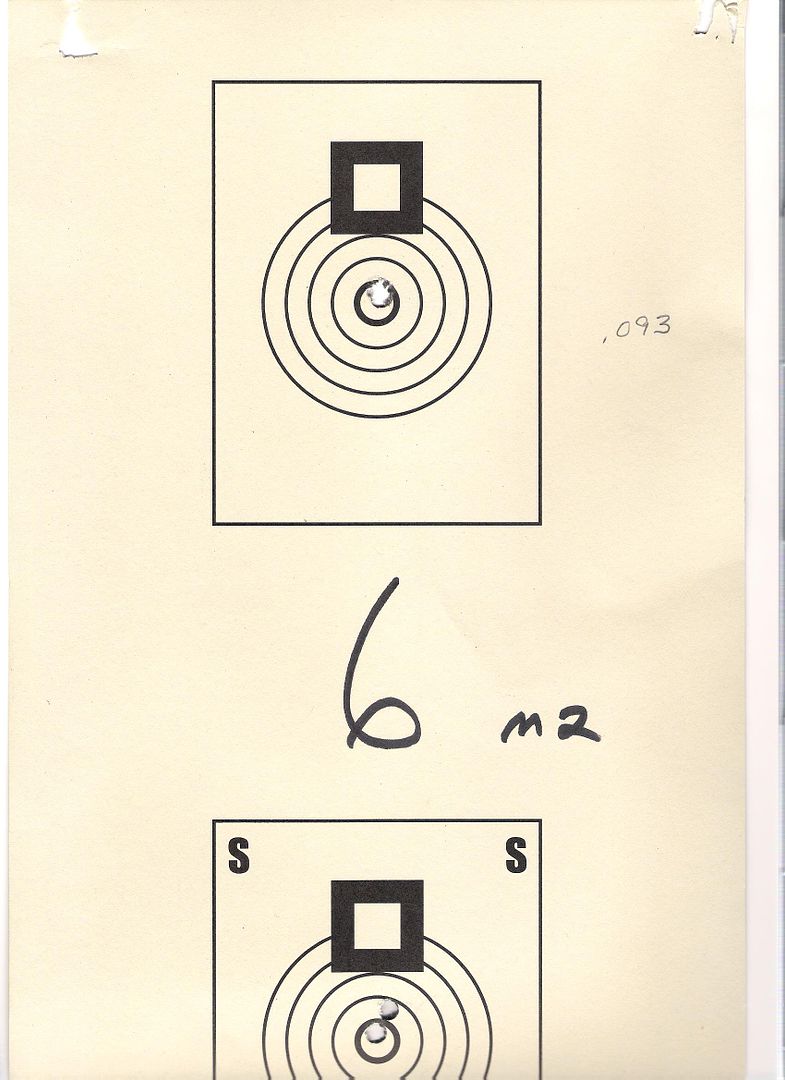

I have yet to see anyone shoot a 5 shoot 100 yard group under .1 with a Lee Collet die.

Reply With Quote

Reply With Quote

Bookmarks