It will only move forward on an empty chamber.

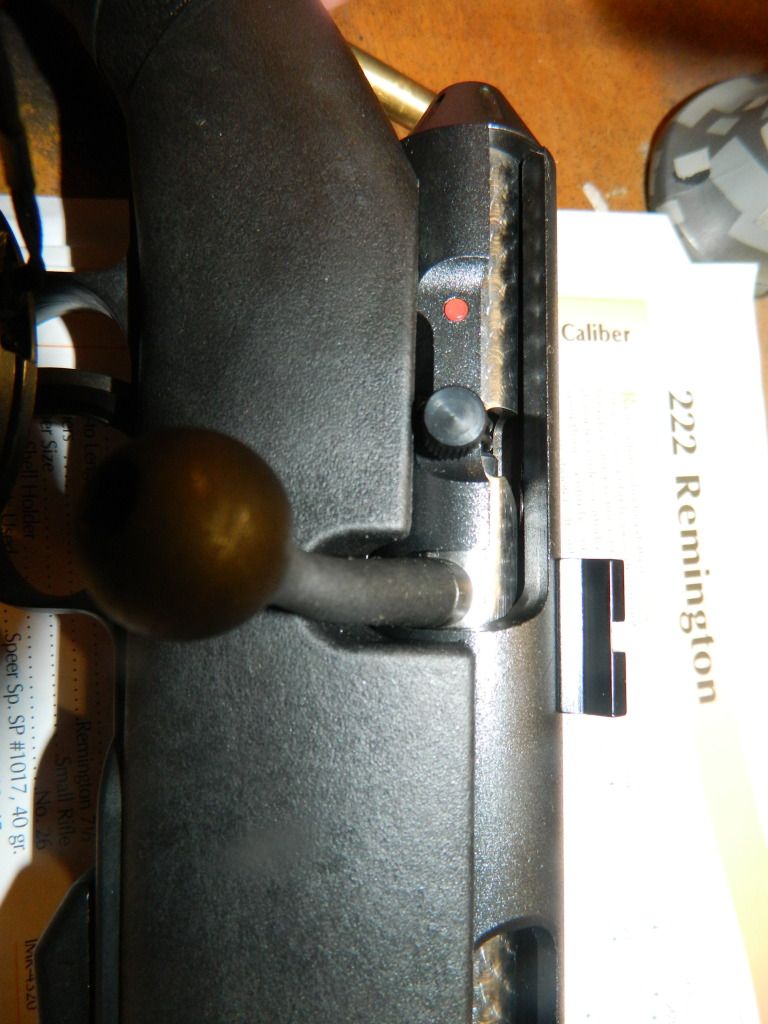

I just picked up a new Model 25 in 222 Rem. But, upon firing the bolt appears to move forward into the receiver. When I go to open the bolt there is a slight rounded edge that comes out from the receiver that makes lifting the bolt very hard. The bolt handle appears to drag on the edge. Just wondering if I can just dremel the receiver's rounded/curved area down or will the bolt just keep moving forward. I have a pic and it is dragging on the front part of the bolt handle. Thanks.

It will only move forward on an empty chamber.

"As long as there's lead in the air....there's still hope.."

Makes sense now. I will check it when I can get some brass. Thanks.

Do NOT grind anything , pretty sure that is your primary extraction cam. You should use some high pressure grease on the shinny surface.

You could try polishing the ramped, cocking port in the bolt body. I've polished the cocking ramp on the back of a mauser's bolt and it made the lift pressure significantly less. The idea is to polish it without removing significant metal. Also, as Gmac5 said, a little high pressure grease helps. I have used a light smear of lithium ball joint grease, which I had in the garage.

More importantly, I'm stunned you found a .222 Remington. I haven't found any listed yet at a couple of distributors, but obviously, the .222 Remington's are getting into the market. If I see one, I intend to grab it.

Hopefully I can get it to the range this week. I have one box of ammo just need to get some dies and brass. I am pretty excited about it also. I never had a 222. Thanks for the info.

@Mr. snowgetter: You should be excited. The .222 remington is frighteningly accurate with just about any powder and bullet combination. With the accu-trigger and the savage barrel, your model 25 should shoot "bughole" groups.

I had a sako .222 rem but gave it to my son many years ago. It would be ungracious to say that I regret doing that, but I will say that I sure miss that rifle. When savage announced the .222 remington chambering in their model 25, I was very happy, and I will be looking for one.

Shot the 222 today and I am impressed. Less than 3/4" groups at 100 with factory loads. Just need to get the dies and brass to perfect it. Bolt lift was not as bad with a fired round in the chamber. It is a keeper.

@Mr snowgetter: That's great performance! But why am I not surprised? I thought the model 25 and the .222 remington would be a good combination.

He/She just pegged it!!

Due to the nature of Cock on Open actions, bolt lift will be stiff. Also as mentioned, primary extraction cam of a bolt action rifle is provided by the bolt handle or bolt contact with the curvature of the rear receiver or any object placed in between the rear ring and the bolt handle, IE the savage 10.

You should not use any abrasive or dremel on these surfaces, EVER, Usually a few hundred cycles of the bolt should help out the smoothness. Just beware that if you start taking off metal with drastic measures you'll start having stuck cases and the rifle may fire in an unsafe condition. It is possible to modify these surfaces but a very intense understanding of its mechanism must be known, respected and not changed.

Bookmarks