Hello all!! I'm hoping there are some antique lovers that can appreciate this rifle. Otherwise, maybe someone can offer some assistance in diagnosing my firing issue.

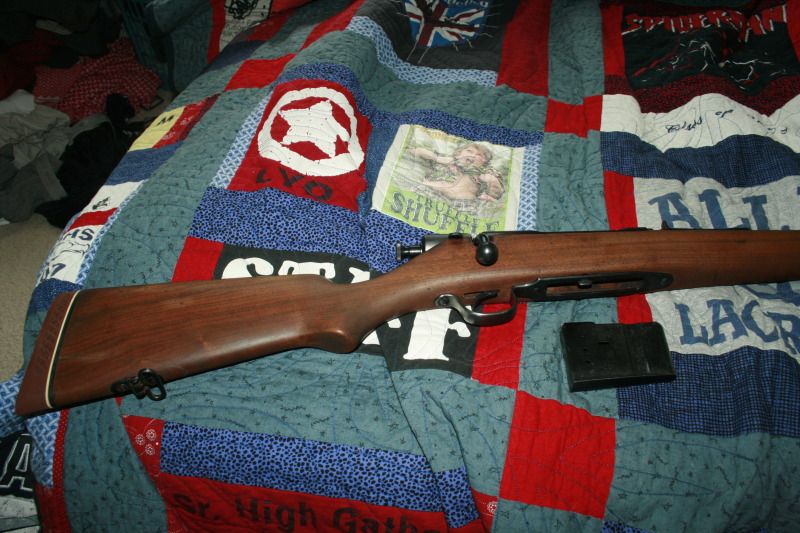

I just inherited (Christmas gift) a Savage Super Sporter .30-06 from my grandfather. The style and serial number (8184) hint to be a pre-1936 production. I've disassembled and cleaned/oiled everything and took it to the range this morning. I know this rifle is not all original, but as I understand these rifles to not bring a lot of money from collectors even in pristine and all original condition. So I'm okay with the alterations. I'm just excited to be hunting deer with the same rifle that my grandfather did. He was my favorite...

[img width=511 height=768]http://img.photobucket.com/albums/v489/InTheNameOfWeez/Guns/_MG_0069.jpg[/img]

The first round fired perfectly and was very accurate. However, the bolt would not release and the brass was jammed inside the action. I had the gunsmith on duty help me out, and he originally thought the round was defective and I should call Federal and inquire about a recall or a replacement of my ammo. The round to cause this issue was a 165 grain .30-06 Springfield round from Federal's Fusion series.

So I reloaded and went back to the range, and had the same thing happen, but not as tight as the first one. I tried another Fusion round, and the same issue occurred, causing a smaller crack than the first, but still present. I tried shooting an old .30-06 round that was left over from 5-6 years ago when he passed away and had been in my backpack, pockets, shelves, and bookcase reminding me to get this gun into clean shape and on to a range so that i could use it this next deer season. I decided to try that round, and there were 0 issues at all. Clean fire, proper bolt release, and a good ejection. The round casing also looks good. I have no idea the grain count or brand, as I don't know where it came from. I then fired 3 rounds of Federal's American Eagle ammunition. Same caliber, but a 150 grain. Those 3 were not as tight as the Fusion, but did still show issues. I fired 6 rounds total. All but 1 jammed the bolt upon attempting to eject the casing. All 6 show a strange pattern that appears to be caused from an impact from inside the casing, and pressing outward onto the barrel. I'm assuming that is what is causing the bolt to become stuck. Every single round except for the single mystery round from ages ago was brand new and off the shelf. No reloads. Never left outdoors. Always in the original box and kept in climate controlled areas.

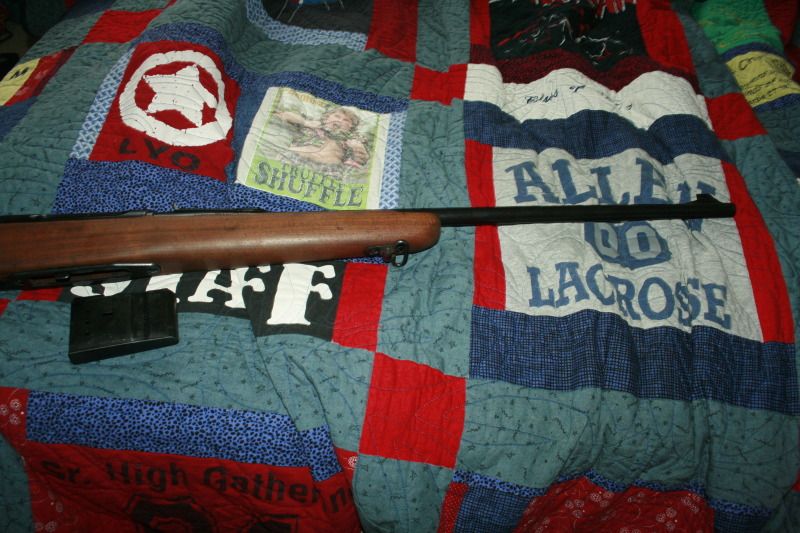

As you can see in the picture, the 1st round that I fired actually warped sideways and had the primer blown out of it. I'm glad I was not injured... 4 out of the 6 rounds show the primer moving out.

So I've found some common marks on the brass and I'm wondering if anyone can give me some pointers. I am completely new to the world of guns and have no understanding of the tolerances that should be adhered to, nor the common failures to cause such an issue. I've searched a bit to try and find a guide to inspecting spent rifle brass for damage and how to diagnose what causes what, but to no avail.

Could someone point me in the right direction to a guide, and what to lead my gun smith into inspecting prior to anything else? From what I found at this site: http://www.exteriorballistics.com/re...aseinspect.cfm

The most common issue would be a headspacing issue. Is anyone familiar with a common cause for improper headspacing or how to correct it? Am I using incorrect ammo for this rifle?

Also, you can see that the rifle has been drilled and tapped for a scope. It was unfortunately taken by my uncle before I got a hold of the weapon, so I am not sure what was installed, but are there any ideas as to what I could mount on here? I would not be opposed to using the top mount rather than side, but side is my first preference simply because it's how my grandfather shot.

Thank you ahead of time for any insight and greetings! ;D I hope someone enjoys the pictures of the rifle. I sure do hope to get it up and running 100% ASAP.

Clayton

Reply With Quote

Reply With Quote

Bookmarks